We have four surprising points at the interview of Iwai Factory.

Vol.1

Iwai Factory

Scroll Down

The day of interviewing 10.31/07.30.2024

Last update 12.11.2024

Hello!

This is Craftman Story Vol. 1. We interviewed Iwai Factory. At this interview, we watched the work od Mr.Iwai and heard about his past works.

When we walk for five minutes from Keikyu-Kamata Station, we can see an old factory on a narrow residential street. This is the Iwai Factory. The Iwai Factory has been in operation since the prewar period. Mr. Iwai, whom we interviewed, took over the factory from his parents and has been doing lathe machining work alone for more than 50 years. He has completed the work of processing parts for nuclear power plants and the Tokaido bullet train. Now, he is processing parts for hydraulic plants.

We have four surprising points at the interview of Iwai Factory.

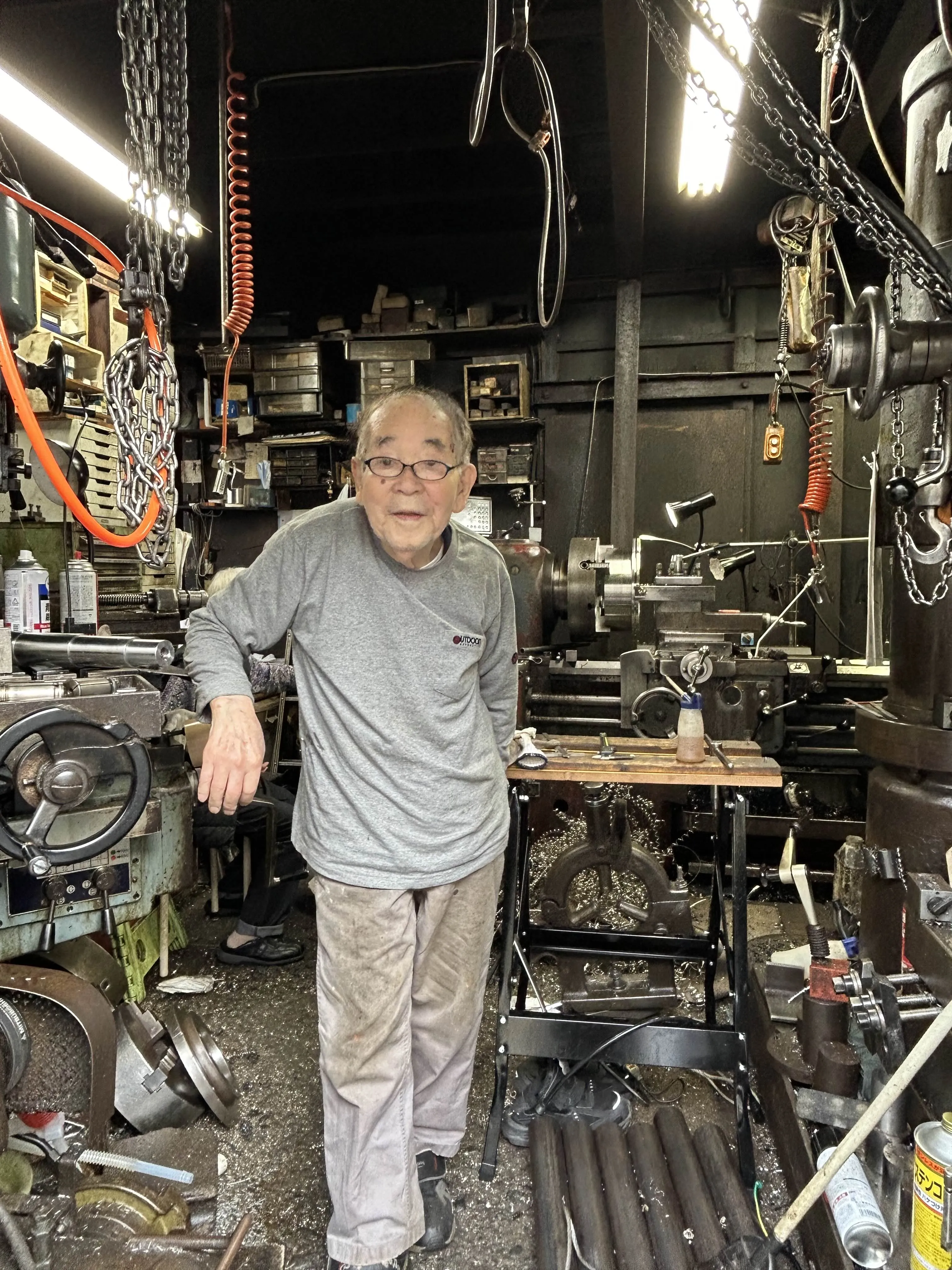

First, we were surprised by the small space of the factory. The Iwai Factory is an isolated two-storey house that includes the Iwai family's home. He works in a room near the entrance. In this room, various kinds of machines and tools take up space, so there is only a small area where three or four students can barely fit.

photo#1 : The appearance of Iwai Factory

photo#2 : Inside the factory

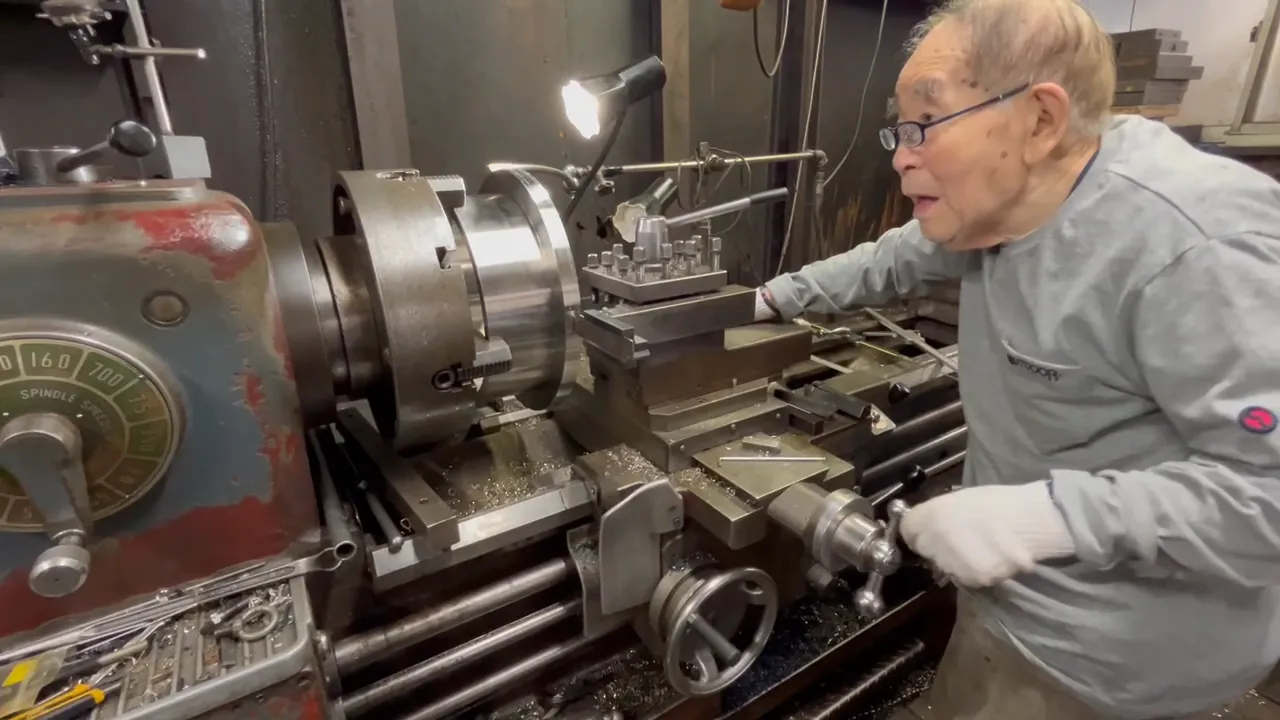

The lathe takes up space in the back of the room. It was manufactured by a company in Okayama and is a third-generation machine. It seems to be well-used. On the floor, there is a lot of iron scrap generated during lathe machining. These emphasize the imposing appearance of the lathe. While we are surprised by the unique atmosphere of the room, which smells like machining oil, Mr. Iwai stands in front of the lathe and starts to handle it.

photo#3 : The lathe

In this interview, Mr.Iwai showed us his work specially for us that he handled the lathe and processed the metal.If you watch the video below, you will feel his work is great, and you will be surprised that the hard metal is processed smoothly. We explain his work in detail below.

(The explanation below is same as the movie above.)

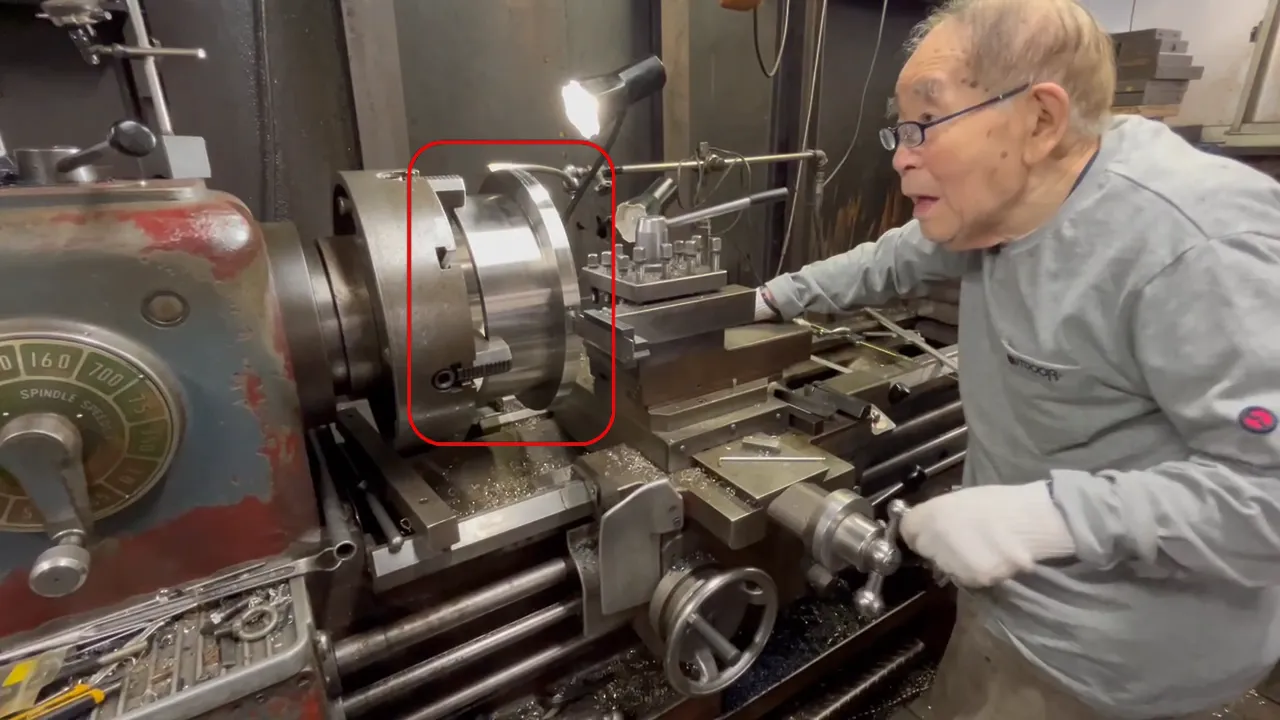

Lathe is a machine that rotates the metal fastly. If we put the knife on the metal that rotates fastly, we can process the metal. The big machine on the photo is the lathe. The metal that we indicate by the red square is the one that is processed. In his work, he digs a ditch on the metal.

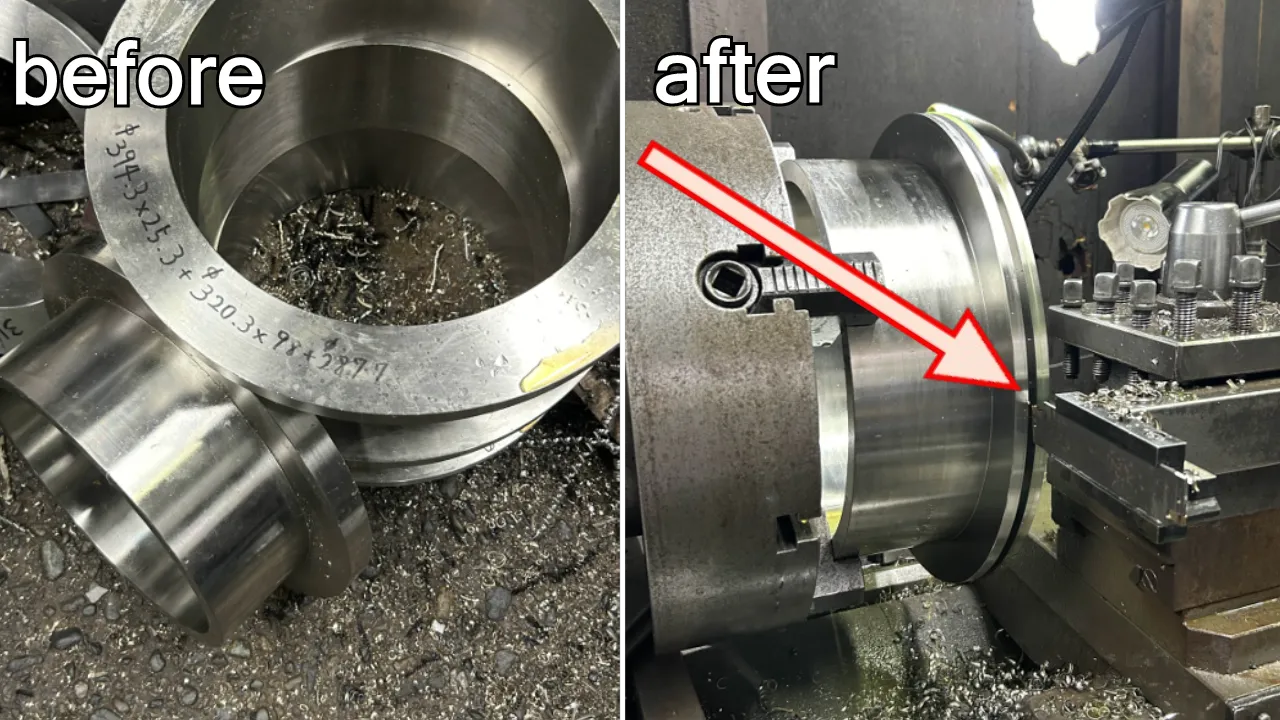

First, Mr.Iwai adjusts the position that he digs a ditch with the meter. Next, he pours the machining oil to slide the metal better. When he turns on the power of the lathe, the metal rotates quickly. Then, when Mr.Iwai adjusts the position of the knife with the dial, the metal starts to be shaven. The more he adjusts the dial, The deeplier the metal is shaven because the position of the knife is changed. the dial, and digs a ditch little by little. He turns off the lathe regularly and checks how deep the metal is shaven.

He repeats these processes. This work seems the same monotonous work over and over. It takes three days that he completes to process a metal.

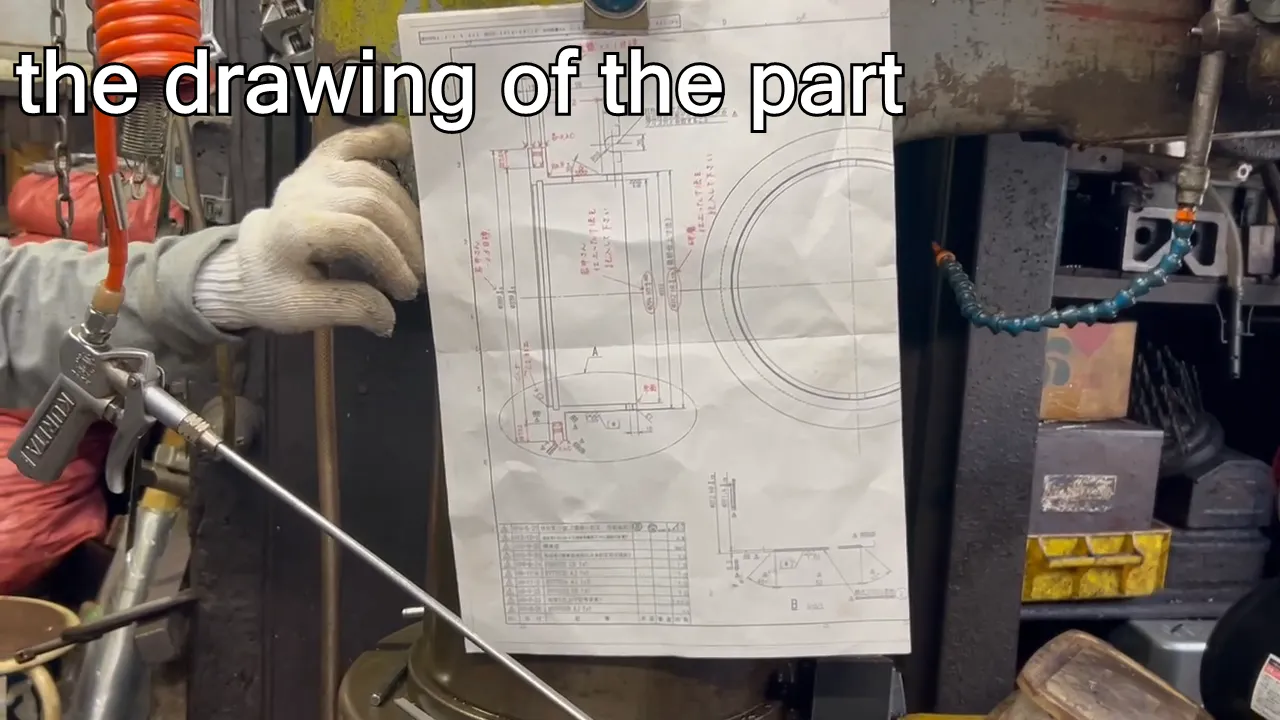

Why doesn't he shave the metal all at once? It seems efficient that he shave it all at once, but he shaves it little by little because accuracy is required to his work. Lathe machining is suitable to accurate processes because it rotates the metal fastly, so we can shave the metal evenly. The metal, that Mr.Iwai processes in this work, is the part of water turbine and we put it with other parts acuurately, so accuracy is required to his work. On checking how accurately the metal is shaven, the craftsman's skill is required.

The metal on the photo is in the middle of his work. We can find it is shaven more deeply than before.

The first big job Mr. Iwai had was processing the parts of the cylinders for nuclear power plants.

It all started when he was asked, “Would you manufacture nuclear power plants with us?” He then tried to manufacture the prototype with an old small lathe machine. His prototype was admired, and he started to manufacture the parts with a big lathe in earnest. This work was pioneering in Japan at that time, so he did it through trial and error.

The hardest part of this job is processing the control rods in the plants. There are about 100 control rods, and we have to handle them simultaneously and keep them in the same position when we stop the plants. This is because if even one of them is misaligned, the plant could overheat. Therefore, high accuracy is required in this process.

Now he do the work to take measures for tsunami, and he has the work to heighten the equipments of the plants for 20 meters all around Japan.

The high level of technical skill cultivated through work on nuclear power plants was recognized, and the job of manufacturing cylinder parts for the Tokaido bullet train also came to Mr.Iwai.

He was involved in the production of cylinders from the 300 series to the 700 series, playing an important role in the operation of the Shinkansen. Particularly during the transition from the 500 series to the 700 series, Mr. Iwai's cylinder technology was utilized, successfully reducing the travel time between Tokyo and Osaka by five minutes. This time reduction allowed for the addition of seven more trains.

Currently, after completing the production of new cylinders with the 700 series, he is focusing on the refurbishment of cylinders.

These tasks require extremely high precision. These episodes highlight Mr. Iwai's high level of technical skill and the fact that small town factories support the daily life of Japan.

Since taking over Iwai Factory, Mr. Iwai has continued to operate it alone. The reason for this is to prevent the leakage of his high level of technical skill. Hiring employees would risk spreading information, so to protect the unique technology of Iwai Factory, he has continued to work alone without expanding the scale. During his solo operations, there were times when people around him suggested he should quit. However, with the encouragement of his wife, he has continued the business to this day.

Although Iwai Factory has been built with the support of the couple, it is scheduled to close with Mr. Iwai's generation due to the lack of a successor. While he has grandchildren and a son, the younger generation is pursuing higher education and shows no interest in work related to nuclear reactors. Additionally, as the area around Kamata Station is becoming more residential, even if the business were to continue, the factory would need to be relocated.

How this technology will be handled by the next generation will be a key issue moving forward.

Our first interview has come to an end. It took just under two hours, but it was very intense. The twists and turns leading up to encountering the lathe, the behind-the-scenes of the nuclear power plant business and bullet train development, and the current and future state of the factory. The numerous episodes we heard from Mr.Iwai through the interview are the very history of post-war Japan. The events we know from textbooks, he witnessed firsthand as a participant. Considering this past, we realize that each step of lathe machining involves advanced technology. Watching him perform tasks where even a single mistake is not allowed, we felt an extraordinary craftsman's spirit.

As we parted, Mr. Iwai said, “You are really young, so you have to support Japan in the future.” The words of this “unsung hero” who has supported our country for half a century carried great weight. The small factory on the corner of Kamata is filled with many secrets and romance built up over many years.

interviewer / writer

interviewer / writer

interviewer / writer / web / video

proofreader

web

web